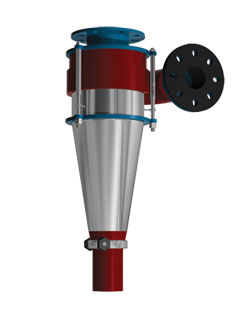

10” Hydrocyclones

Tega 10” Hydrocylone is made of high wera rsistant polyurethane and is light in weight. The cyclone polyurethane parts are enclosed in stainless steel casing, which are held together by steel plates and stainless steel studs. Simple and quick release type of clamp system is provided for spigot fixing.

|

Tega 10” Hydrocylones are mainly used in

|

Tega 10” Hydrocyclones are available in single units and for larger flow rates cyclones are supplied in radials. These radials can accommodate up tp 16 number of cyclones.

Features |

Benefits |

| Specially designed feed inlets | Reduces turbulance and wear |

| Additional cylindrical sections | Produces finer cut points |

| Available with different cone angles | Operates at higher capacity |

| Simple stud fixing arrangement and spigot fixing by clamp system | Provides better separation/capacity |

| Ceramic lining parts are available | Makes maintenance easier |

| Helps in finer size classification | |

| For treating abrasive feed materials |

Specifications:

Following tables show operating capabilities of single unit of Tega 10” Hydrocyclone. The capacity, cut size and volume split to underflow depends on the size of the vortex finder and operating pressure (0.68 – 2.04 kg/cm2)

Vortex Size(mm) |

Capacity*(m3/hr) |

Cut Size µm |

Volume Split to Underflow+,(%) |

| 100 | 38 – 80 | 45 – 46 | 0 – 9 |

| 80 | 34 – 50 | 37 – 38 | 0 – 63 |

| 60 | 16 – 36 | 30 – 31 | 0 – 100 |

| 45 | 10 – 26 | 24 – 25 | 0 – 100 |