Heat Exchangers

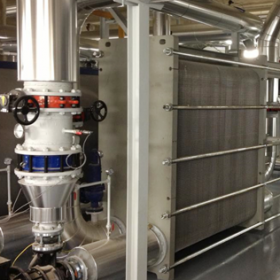

Gasketed Plate Heat Exchangers

Gasketed plate heat exchangers have numerous applications in industry, in heat recovery processes, and air- conditioning applications. Plate heat exchangers are available with ordinary, free flow or semi-welded plates.

Plates are tied together in a plate pack with each plate sealed to the next by means of a gasket. Gaskets are supplied in a range of materials suited to the specific application.

Spiral Heat Exchangers

IWC are official agents for the Nexson Group’s range of spiral heat exchangers.

Circular in design with two spiral channels; each one is a closed chamber allowing for the two products to remain separate while heat exchange occurs.

The flow of the two products is usually counter current which results in a close temperature approach between the two media. A variety of fluids can be circulated through this type of heat exchanger, including liquids containing solids and fibres, waste water and slurries to name a few.

The heat exchanger is easy to clean and maintain as it has side frames on hinges which open to allow access to the internal spirals.

Copper Brazed Heat Exchangers

Brazed plate heat exchangers consist of a number of thin, acid resistant plates, precision stamped and assembled as a unit. The plate pack, assembled with two end plates and connections, is vacuum brazed at extremely high temperatures providing a permanently sealed heat exchanger.

This results in an efficient unit which gives a space and weight saving of up to 80% compared with a tube heat exchanger. These plate heat exchangers are suitable for applications requiring high temperatures and pressures. Brazed plate heat exchangers do not contain rubber gaskets and can therefore operate continuously at extreme temperatures from -180°C to 200°C with operating pressures as high as 30 bar. Applications where these heat exchangers are an effective solution include heating and ventilation (for solar heating and air-conditioning units), heat pumps, heat recovery, and hydraulic oil units.

Semi and Fully Welded Plate and Shell Heat Exchangers

Thermal efficiency in a welded heat exchanger is comparable to a traditional gasketed plate heat exchanger.

Compared to shell and tube heat exchangers, welded units take up significantly less space. Plate and shell heat exchangers work in the same way as an ordinary tubular unit; however, they are more efficient due to the use of plates instead of tubes. Plates are laser welded together to form a plate pack, which is then mounted inside a traditional cylindrical shell. The heat exchanger is produced as an all welded exchanger or with flanges which makes manual cleaning possible.

The all welded heat exchanger is built into a frame with its welded plate pack. These units can operate with temperatures from -100°C to 400°C and with design pressures of up to 40 bar. These heat exchangers can be used to cool aggressive media and applications include power plants, petrochemical, pulp and paper, steel and sugar industries.